1그것은 고급 인간-기계 대화 CNC 시스템, G 코드 프로그래밍 및 도구 소프트웨어로 장착 될 수 있습니다. 시스템은 안전하고 안정적이며 편리하며 전자기 간섭에 저항합니다.CNC와 PC 사이의 프로그램 전송은 이더넷 인터페이스 및 USB3를 통해 실현 될 수 있습니다..0, 가장 짧은 처리 준비 시간과 한 번의 클릭으로 시작하여 생산성을 크게 향상시킬 수 있습니다.

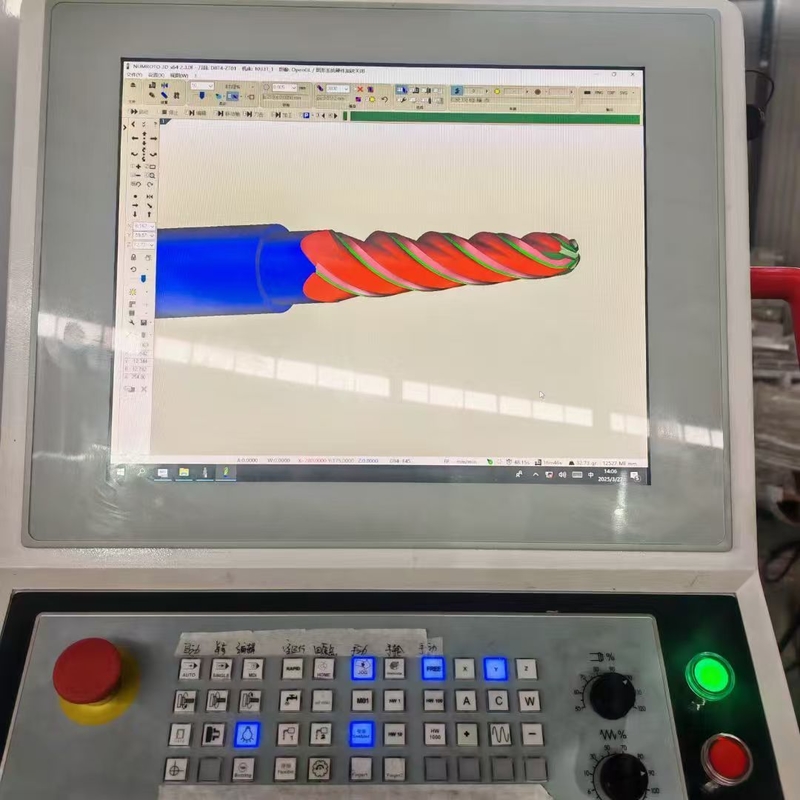

23D 시뮬레이션 소프트웨어가 장착되어 있어 대화 상자에 필요한 도구 처리 매개 변수를 표시합니다. 매개 변수 입력 후,도구 시뮬레이션은 도구의 3D 그래픽과 기계 도구의 밀링 단계를 표시 할 수 있습니다..(각 닦기 단계를 다른 색으로 구별하십시오) 실제 과정에서 충돌 현상을 피하기 위해 소프트웨어의 충돌 방지 기능을 사용하십시오.해당 소프트웨어 모듈을 선택 다양한 도구를 처리 할 수 있습니다, 탐사선을 통해 작업 조각의 자동 주기 측정과 도구 마모 보상, 도구를 생산하고 수리 및 날카롭게 할 수 있습니다.

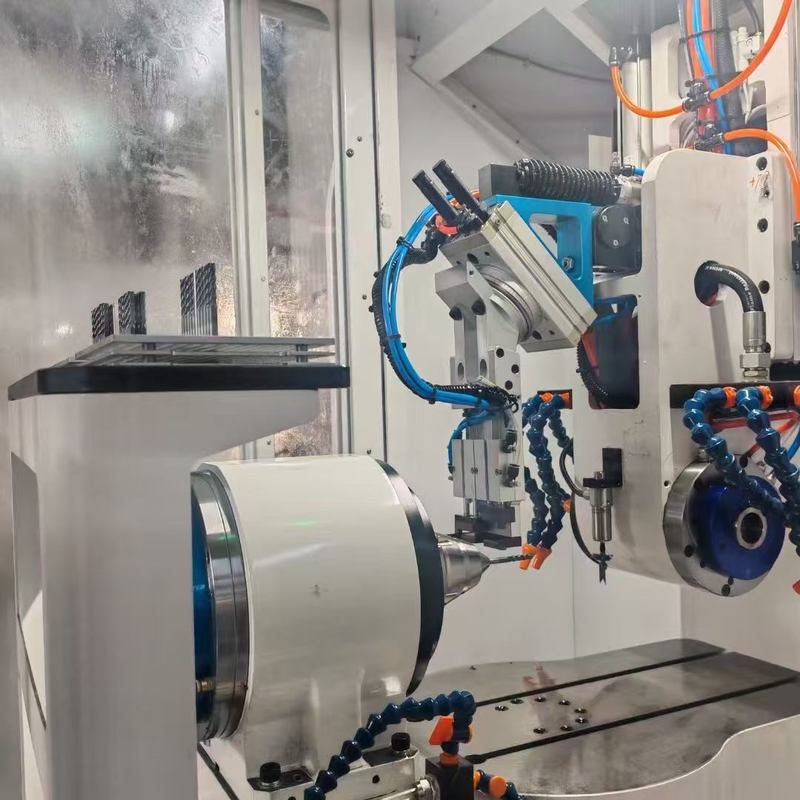

3무거운 디자인, 높은 힘, 턴트리형 폐쇄 구조, 좋은 딱딱성, 높은 강도, 좋은 안정성.

4원본 수입 나사, 가이드 레일, DD 모터 A, C 축 고정도 회전대, DD 모터는 R 각 정확성, 강한 민감성, 좋은 안정성,도구 밀링 정확성 및 처리 효율성을 향상.

5X/Y축은 선형 모터로 고정도 격자 릴리어를 탑재하여 부품 마모를 크게 줄이고 더 높은 정확성, 더 빠른 반응 및 더 높은 처리 효율성을 가지고 있습니다.

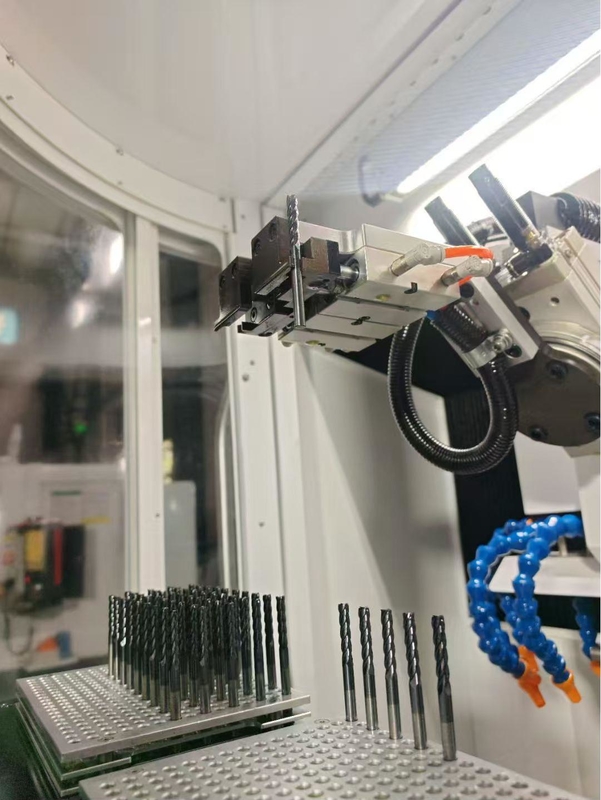

6사용자 필요에 따라 정밀한 6축 기계 팔 또는 자동 부하 및 부하를 실현하기 위해 자체 제작된 부하 및 부하 장치를 선택할 수 있습니다.자동 연료 충전 및 제품 처리가 무인 조작으로 동시에 수행 될 수 있습니다., 도구 밀링 기계의 생산 효율을 크게 향상시킵니다.

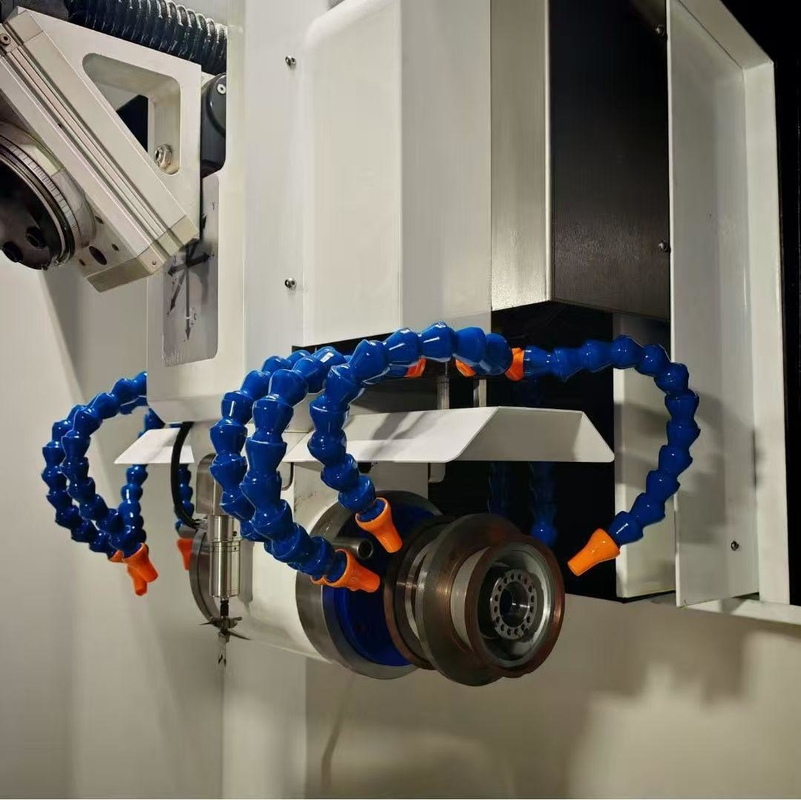

7이중 연장 전기 스핀들, 큰 토크, 무거운 쇄력. 이중 연장 스핀들에는 6-8개의 쇄 바퀴가 장착될 수 있습니다.비표준 도구 및 닦기 도구 가공에 적합합니다..

8,중심 및 긴 도구 생산을위한 간단한 지원으로 장착.

적용 분야:

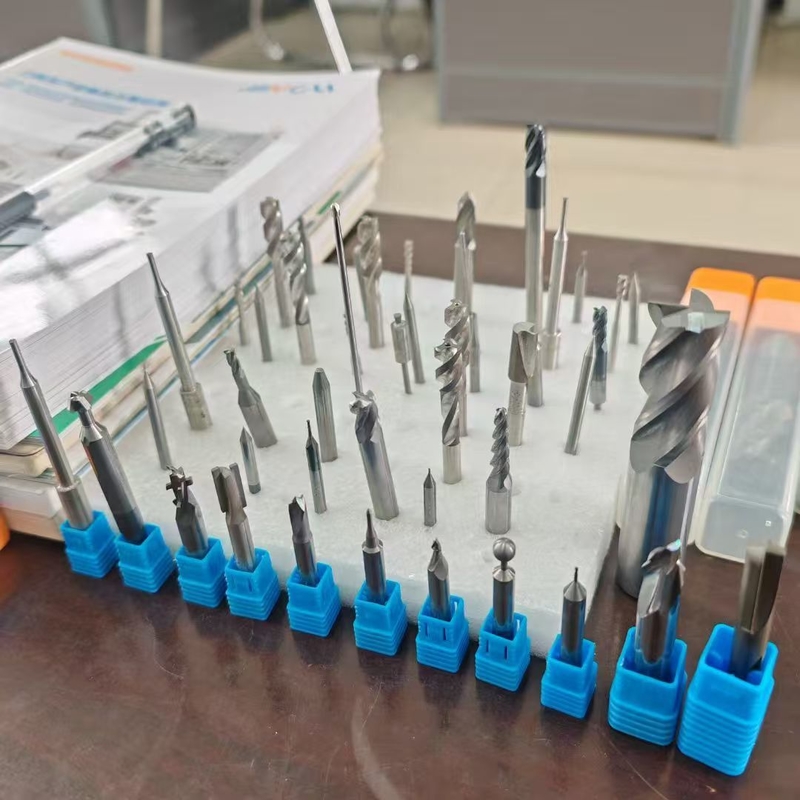

1가공재료: 고속제철, 탄화물 및 스테인리스제철 등

2류: 직각 류, 톱니 직각 류, 나선 류, 톱니 나선 류.

3굴착형: 직선 굴착, 나선 굴착, 직선 굴착, 나선 굴착

4"밀링 커터: 평면 머리 칼, 톱니 평면 머리 칼, 둥근 코 넥타이, 타버노스 칼, 공 머리 칼, 톱니 공 머리 칼.

5"다양한 표준 및 비 표준 도구 가공. 제품 부품의 5 축 연결 쇄.

제품 세부 사항:

제품 파라미터:

| 모델 |

단위 |

MG300 |

MG200 |

MG100 |

| X축 이동 |

mm |

950 |

800 |

600 |

| Y축 이동 |

mm |

520 |

400 |

350 |

| Z축 이동 |

mm |

250 |

220 |

200 |

| A축의 도동 |

|

연속 360° |

연속 360° |

연속 360° |

| C축 이동 |

° |

±180° |

±180° |

±180° |

| X/Y/Z 축의 위치 정확도 |

mm |

0.005 |

0.005 |

0.005 |

| XYZ 축의 반복 위치 정확도 |

mm |

0.003 |

0.003 |

0.003 |

| A/C 축의 위치 정확도 |

|

±5Arc초 |

±5Arc초 |

±5Arc초 |

| A/C 축의 반복 위치 정확도 |

|

±2Arc초 |

±2Arc초 |

±2Arc초 |

| 스핀드의 명력 |

kw |

24kw |

18kW |

10kW |

| 스핀드 속도 |

rpm |

0-6000 |

0-6000 |

0-6000 |

| 밀링 휠 막대기 모델 |

|

HSK50E |

HSK50E |

HSK50E |

| 설치할 수 있는 밀링 휠의 수 |

pcs |

6~8 |

6~8 |

6~8 |

| 가장 큰 밀링 휠 지름 |

mm |

150 |

150 |

150 |

| 톱니 톱니 |

|

BT2사업자 |

BT2사업자 |

BT2사업자 |

| 최대 썰기 길이가 |

mm |

블레이드 길이는:260,

전체 길이는:300

|

블레이드 길이는:160,

전체 길이는:200

|

블레이드 길이는:70,

전체 길이는:100

|

| 작업 조각 손잡이의 최소 지름 |

mm |

3 |

3 |

3 |

| 작업 조각 손잡이의 최대 지름 |

mm |

32 |

20 |

12 |

| 작업 조각의 최저 절단 가장자리 지름 |

mm |

1 |

1 |

0.5 |

| 최대 직경 |

mm |

200 |

150 |

100 |

| 작업 공기 압력 |

MPa |

00.6~0.8 |

00.6~0.8 |

00.6~0.8 |

| 냉각 용액 유동량 |

L/min |

85 |

85 |

85 |

| 장비의 총 전력 |

|

35KW ((3단계 AC380V) |

25KW ((3단계 AC380V) |

20KW ((3단계 AC380V) |

| 길이 * 너비 * 높이 |

mm |

2500*2500*2500 |

2200*2500*2200 |

2100*2200*2400 |

| 장비의 총 무게 |

T |

6 |

5 |

4 |

우리 서비스:

고품질의 기계를 받을 수 있도록

1모든 부품이 검사되어야 합니다.

2100개 이상의 생산 프로세스 제어

3200개 이상의 검사 항목

4각 기계의 샘플 처리

5배달 전 72시간 시험 운행

우리 를 선택 하는 이유:

◆ 최고 품질 의 감각, 고객 의 요구 가 우선

◆ 30 년 + R & D 역사, 회사는 1993 년 설립 되었습니다

◆ 연구 및 설계 능력을 가진 첨단 기술 제조업체

◆ 안정 하고 성숙 한 공급 시스템

◆ 젊은 활동적 인 영업자 들 과 엔지니어 들 은 즉각적 인 서비스 를 제공 합니다.

◆ 에르고노믹 과 간편 한 유지 보수 에 따라 기계 의 업그레이드

◆ 우리 의 구조 설계 원칙: 간편 한 유지 보수 및 설치, 낮은 유지 보수 비용, 생산 에 영향을 미치지 않습니다

우리 에 관한 것:

방문해 주세요!

상하이 HD M&E 테크 Co., Ltd는 중국 상하이에 위치하고 있습니다. 우리는 CNC 톱니, 수직 가공 센터, 수평 가공 센터, 게트리 가공 센터, 5 축 가공 센터,턴밀링 센터 및 기타 다양한 CNC 장비우리는 200종 이상의 기계 도구를 가지고 있습니다. 제품의 품질과 기술은 국제적인 고급 수준에 도달했습니다.

우리 공장은 80년이 넘는 기계장비 제조 역사를 가지고 있습니다. 첫 번째 톱니바퀴, 굴착 기계, 굴착 기계가 모두 이곳에서 탄생했습니다.그들은 중국의 기계 도구 산업의 리더 중 하나이며 중국에서 가장 큰 기계 도구 제조기계 도구 제품은 자동차, 항공, 새로운 에너지, 건설 기계, 선박, 펌프 밸브, 베어링, 3C 전자제품, 곰팡이 및 기타 산업을 포함한다.우리는 선도적인 기술을 기계 도구 제공의 임무를 수행, 고품질과 좋은 서비스를 전 세계 고객에게!

우리 공장:

FAQ:

Q1. 당신은 무역 회사 또는 제조 회사입니까?

우리는 제조 회사입니다.

Q2. 회사의 주요 제품은 무엇입니까?

우리는 모든 종류의 기계에 특화되어 있습니다. 예를 들어 CNC 라트, CNC 프레잉 머신, 수직 가공 센터, 전통적인 라트, 드릴링 머신, 방사선 드릴링 머신 등.

Q3. 당신은 사용자 정의 기계 또는 SPM (특수한 목적 기계) 를 제공 할 수 있습니까?

예, 우리는 효율성을 높이기 위해 우리의 고객을 위해 스마트 CNC 솔루션을 제공합니다.

Q4: 보증 조건은 무엇입니까?

우리는 12개월 동안 결함이 있는 부품을 교체할 것입니다.

기계의 화물표 날짜부터 시작됩니다.

Q5. 서비스 는 무엇 입니까?

프-세일: 맞춤형 솔루션, 계획 및 디자인;원대원 서비스

판매 후:7 일 24 시간 라인 서비스, 설치 원격 지도, 고객 소프트웨어 시스템과 도킹

Q6: 왜 당신 회사를 선택하셨나요?

전체 생산 과정의 개발, 설계, 제조, 조립에서 나오는 제품은

생산망이 전체적인 공장들 사이에 이루어집니다.

Q7: 당신의 회사는 기술 인력을 우리 회사로 보내 해외에 우리의 노동자를 지시 할 수 있습니까?

우리는 이러한 서비스를 제공할 수 있습니다. 기계가 구매자의 설치 현장에 도착하면, 우리는 구매자의 일정에 따라 설치를 위해 기계 및 전기 엔지니어를 적시에 보낼 수 있습니다.이 모든 것들은 계약서에 인용되고 나열될 수 있습니다.판매자는 외국에 가기 전에 비자 및 설치 준비를 처리하기 위해 구매자와 협력합니다.

Q8: 지불 조건은 무엇입니까?

T/T 주문 시 30%의 초기 지불, 배송 전 70%의 잔액 지불

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!